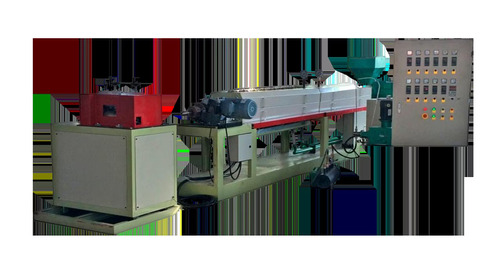

EPE Foam fruit net machine

Product Details:

EPE Foam fruit net machine Price And Quantity

- 1800000 INR/Piece

- 1 Piece

EPE Foam fruit net machine Trade Information

- Paypal Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Delivery Point (DP) Letter of Credit at Sight (Sight L/C)

- 10 Piece Per Week

- 15 Days

- Contact us for information regarding our sample policy

Product Description

EPE Foam fruit net machine efficiently produces protective fruit nets, ensuring each item is securely wrapped and protected during transportation and storage. Using expanded polyethylene (EPE) foam, it creates soft, flexible nets that prevent bruising and damage to delicate produce. The process is quick and highly automated, reducing labor costs while maintaining consistent product quality. EPE Foam fruit net machine is ideal for businesses seeking a cost-effective and reliable solution for packaging fruits and vegetables, offering a durable, lightweight option for a variety of produce types.

Components:

-

Foam Material Input: A section for loading raw foam materials, often in rolls or sheets.

-

Cutting Mechanism: A system to cut the foam into desired sizes and shapes suitable for different types of fruits.

-

Forming Unit: A part that molds the foam into net-like structures, often using a combination of heat and pressure.

-

Conveyor System: For transporting the formed netting through various stages of production.

-

Winding and Packaging Unit: For rolling the finished foam netting and preparing it for shipping.

-

Control Panel: An interface for operating the machine, monitoring production speed, and adjusting settings.

-

Safety Features: Emergency stops, guards, and other safety mechanisms to protect operators.

Features

- Adjustable Size Settings: Allows for customization based on different fruit sizes.

- High Production Speed: Designed to efficiently produce large volumes of foam netting.

- Energy Efficiency: Modern machines are often designed to minimize energy consumption.

- User-Friendly Interface: Simplifies operation for users with varying levels of technical expertise.

- Durability: Built to withstand continuous operation and heavy usage.

Applications

- Fruit Packing: Provides cushioning and protection for delicate fruits during transportation.

- Export Packaging: Ensures fruits remain undamaged during long-distance shipping.